C3200 D

Ergonomics, quality and accessibility

3200 L

Capacity

1280 Kg

Nominal load

1263 mm

Aperture height

Different solution for each type of collection

The side-loading 3,200 L container is manufactured from injection-moulded polyethylene, using state-of-the-art machinery and moulds, together with environmentally-friendly, recyclable materials. Injection moulding makes it possible to take advantage of the benefits of plastic, including stable colours, full corrosion resistance, smooth surfaces and the ability to withstand everyday impacts without denting or cracking.

The C3200 D is specially designed for use with all standard collection equipment. It has GS product certification from TÜV Product Service GMBH in line with the following European standards: EN 12574-1 (design); EN 12574-2 (product testing); and EN 12574-3 (safety). This guarantees users and operators that the product meets the strictest requirements in terms of health and safety, size and mechanical strength.

The maximum floor gradient for use of the 3,200 L container is 20° and it has a tractive force of 68 N with the container at an incline of 6°.

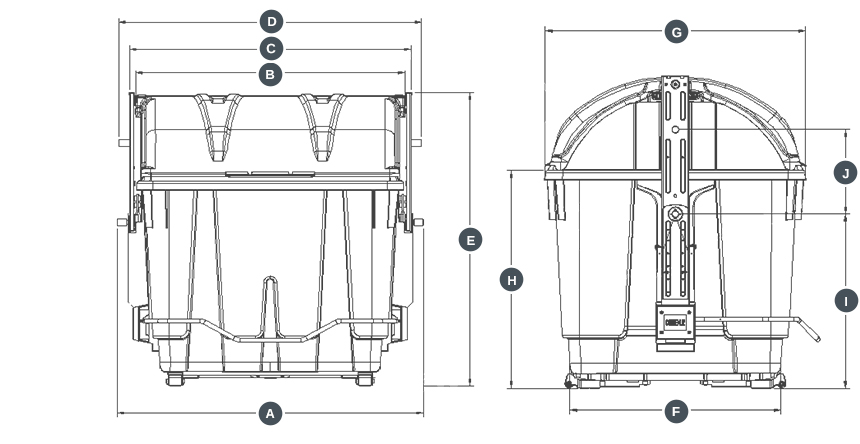

TECHNICAL SPECIFICATIONS

- A > 1887 mm

- B > 1660 mm

- C > 1737 mm

- D > 1870 mm

- E > 1810 mm

- F > 1223 mm

- G > 1510 mm

- H > 1263 mm

- I > 1010 mm

- J > 490 mm

CAPACITY

3200 l

NOMINAL LOAD

960 kg

Customisation

Equipment for all needs

Available in variety of colours

CONTENUR products can be supplied on order in a wide variety of colours. The high-density mass-coloured polyethylene injection system is stabilised against the combined action of water and Ultra Violet rays.

The high-density polyethylene enables the product to easily withstand the elements and makes it extremely stable when faced with temperature changes. Recyclable materials that do not have a negative environmental impact are used, as well as pigments that do not contain heavy metals, which means that the colours remain inalterable.